On Ravelry I found a link to an article on a really fantastic Very Big mangle.

To ensure I don't lose the link, I decided to post it here, too: https://craftsmanship.net/ancient-mangle-santarcangelo-di-romagna/.

(there is a video, too)

05/10/2019

29/11/2017

goose eye combined w plain weave and basket weave?

Can "goose-eye" be combined w other structures?

Well, not all of them... at least not if using 4 shafts.

Well, not all of them... at least not if using 4 shafts.

Labels:

combining structures,

twill,

weave construction

10/06/2017

More about making sure that heddles can’t fall off the end of the shafts

As it seems that the article on "how to secure lease sticks" on my web page is not very clear, here are some more pictures and some more words.

First, it seems that the title of the page is making confusion: why is it about lease sticks? (and – if the method is for lease sticks, then, surely, it isn’t good for the use on shafts, is it?)

So. Starting with the lease sticks.

Why would one want another method than tying them together, so that the pair is "fixed together"?

I can see several reasons: for a very dense and/or sticky warp (warp rep with, say, 36 ends of cotton 16/2 per cm, approx. 140 ends per inch, is one example – another can be a brushed mohair for warp, can get sticky even at open setts) – for the dense or sticky warp it will be so very much easier to move the lease sticks separately.

Another reason can be that moving a folding loom about in its folded state: my folding looms need the warp tension to be slackened for folding, which means the lease sticks can slip around. Then this can happen:

Granted, it is quite possible to get the warp back onto the sticks, but it takes more fiddling (at least for me) – and so I use this method ’cos I find it faster and easier.

This is what it looks om my big loom (the blue stripe was an afterthought, and narrow enough not to need a lease for the sample I’m making):

Back to the folding loom (used mainly for demos): it will never, ever get folded without security strings on the shafts bars.

(One of my students thought that "sissy", folded the loom and carried it away. The lower bars promptly fell out, because she had not tied the treadles yet. It took hours to get them back, with the correct heddles on the correct lower shaft bar, in the correct order. She added security strings...)

So this is how it looks:

I always put the "handle" for opening (the knot with its tails) on the left side, because I thread from right to left – if I need to add (or take off) heddles while/after threading, this will always be done on the left side.

(Fow to make this style of security string, pls refer to the web page, linked above)

But, some of you say, why not just connect the upper shaft bar with the lower shaft bar?

AVL does this, by sticking a long metal rod from top to bottom

So what will happen if you just tie them together with a piece of string? (The black string may be hard to see, but click the pics to biggify - it should be easier to see)

OK, it will not happen every time, but it sure can happen, especially if you are using the whole width of the loom.

The heddles will not fall to the floor, it will be easy to know which shaft they belong to, that is true. However, should this happen to the outer heddles, there will not be any shed at the selvages... and it would require fiddling to get the heddles back.

Again: I find it so much easier to secure the heddles in a way that ensures me that they stay in their place.

Yes, I know: there are no safety strings on this loom for the moment. Next time I’m going to weave wide I will put them on... or, maybe, next time I get annoyed at having to get the fallen-to-the-floor unused heddle back on. Nobody is perfect...)

Edit - adding:

It did not occur to me when writing, but: the top-to-bottom connector string - how to handle that when one wants to add/subtract heddles? This possible connxion can, as can the other "knotted strings", be tied with an easily undone knot (bow?). Otherwise it will also hinder the heddle handling...

20/02/2017

"Alternative news" from Sweden

My very busy half-year is (hopefully) soon coming to an end: in October my mother (97) moved to a so called service apartment.

"Down-sizing", anyone?

I have been carting things here and there, to her new place and to me (and some to second-hand and the dump, too). But now I can see the end of all this – her old apartment is going on the market in a couple of weeks. (After I have taken one last load down here... - faamous lsat words?)

Last week I came home with a well-travelled suitcase, containing a jacket, an experimental moebius scarf (made by me) and some small yardage pieces (woven by her) – also some glass pieces for our growing museum, and some for re-homing.

(I really like how the back of the hood came out!)

Also, plans start to emerge for the Event of the Year: VÄV2017, this time at a place near me.

Oh yes – what happened in Bergdala, Sweden last Friday: grey/rainy weather with icy roads, the snowdrops got visible again after the rain, the assiettes got re-homed and the service workshop ordered a new part for my new computer. Even if the wind sometimes was hard, there were no earth-shaking events (but the aspen across the lane still looks like it will fall with the smallest gust of wind).

So there!

"Down-sizing", anyone?

I have been carting things here and there, to her new place and to me (and some to second-hand and the dump, too). But now I can see the end of all this – her old apartment is going on the market in a couple of weeks. (After I have taken one last load down here... - faamous lsat words?)

Last week I came home with a well-travelled suitcase, containing a jacket, an experimental moebius scarf (made by me) and some small yardage pieces (woven by her) – also some glass pieces for our growing museum, and some for re-homing.

(I really like how the back of the hood came out!)

Also, plans start to emerge for the Event of the Year: VÄV2017, this time at a place near me.

Oh yes – what happened in Bergdala, Sweden last Friday: grey/rainy weather with icy roads, the snowdrops got visible again after the rain, the assiettes got re-homed and the service workshop ordered a new part for my new computer. Even if the wind sometimes was hard, there were no earth-shaking events (but the aspen across the lane still looks like it will fall with the smallest gust of wind).

So there!

Labels:

block weave,

clothing,

curiosities,

dräll,

Moebius,

twill

02/12/2016

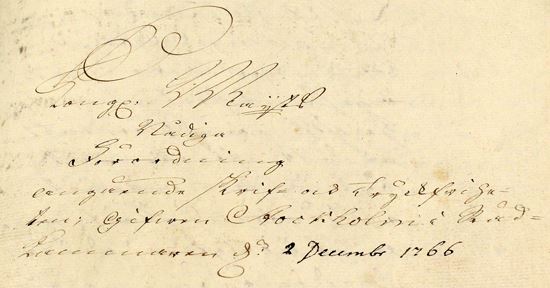

Happy birthday!

Today the world's oldest Freedom of the Press Regulation is 250 years old.

And what's more: it is the Swedish Freedom of the Press law!

Read more at https://frittord250.se/!

This post ought to be labeled as "essentials", but will instead get the label "curiosities".

To make some sort of textile connexion, here are some text messages:

And what's more: it is the Swedish Freedom of the Press law!

Read more at https://frittord250.se/!

This post ought to be labeled as "essentials", but will instead get the label "curiosities".

To make some sort of textile connexion, here are some text messages:

22/09/2016

Double layers and "clean cuts"

Jean's comment on the differences on right and left (or top and bottom) made me do what I have thought to do for a long time: can the differences be avoided?

So I started with my "normal", looking at both sides:

Seeing that both sides are the same (one side clean, the other jagged) made me suspect that it can't be "fixed", as long as one is interested in a reversible result.

By adding (or subtracting) two ends at the jagged side, one can get clean cuts at both sides.

... but the back will then get both sides jagged:

Personal conclusion: until I feel the urge to take the exchanging layers to twill, I will continue to weave two picks per layer, and live with the un-equal sides because of the reversibility of the result.

Others may have other ideas...

Labels:

block weave,

double layers,

weave construction

13/09/2016

Triple layers - variation for easier weaving

Yesterday I stopped before doing what I always do: rearranging the treadling for easiest actual weaving:

Unless I have very fat yarns in my double (in this case triple) cloth, I try to arrange the treadling so that I can do two picks per shuttle (layer).

It is so much faster to do two picks before having to change shuttles...

(Yes, it shows in the end product:

These are two not quite focussed pictures of double-layer shawls.

They are approximately 2 x life size, and has the ends one-by-one and the picks two-by-two.

The warps are a combination of cottons, 16/2, 20/2, 22/2 and maybe a few 30/2.

The wefts are of course only one quality per shuttle, but I don't remember which grist. The sett was probably somewhere about 10 ends/cm (25 epi).

And no, I haven't tried it for three layers.)

So: here is what I would do before sitting down to actually weave.

First: use the existing tieup, but rearrange the colour sequence.

Next: rearrange the new treadling to straight:

As I weave from bottom to top, and have an overhead beater, this is the treadling I would use, namely start in the bottom layer, working up to the top layer, as seen in the widest section of the warp.

(Yes, on the loom there will be "gaps" where the layers change. I have never seen these gaps after wet finishing - see pictures above.)

Hm.

Remembering one of my doodlings from yesterday (which did not reach publication) - another way of making more-than-two-different narrow stripes - a shift in the warp sequence can accomplish that:

Of course it depends on the actual colours used etc etc, but something to consider, perhaps?

Labels:

block weave,

efficiency,

plain weave,

triple layers,

weave construction

Subscribe to:

Comments (Atom)