Showing posts with label counterbalance looms. Show all posts

Showing posts with label counterbalance looms. Show all posts

07/09/2016

Dräll pulleys and opposite tie-ups, again

So is it possible to use dräll pulleys for other than two-block "opposite" weaves?

To refresh your memory, here is one illustration from my web page on dräll pulleys, with 6 shafts mounted:

The question came up in another context, and I tried to construct some examples.

Starting with a 2/2 twill - this is one "normal" way to thread and tie it up:

(The red line represents the position of the dräll pulley, the line which makes the mirror for the opposite tieup)

As can be seen, that tieup will not work. Starting from the left, the first column will work. The second will not, as shafts 1 and 4 both go up (in the Swe notation), while shafts 2 and 3 both go down). Third column is "opposite", fourth is not.

So what can be done? We need to do something to both column 2 and 4, trying to get them "opposite". One way is this:

By changing the threading, we have also changed the tieup, which is now compatible with the dräll pulleys: it is now "opposite". (Note that this also prevents a true tabby, as the threading no longer follows the odd-even rule).

Next try, an 8-shaft even tieup (by "even" I mean that all sheds have half of the shafts up, half down, in various combinations - see a discussion on "even" weaves here)

Started with the leftmost column - and got the fourth correct as a bonus.

However much I tried, I could not fix more than 4 columns/treadles.

Maybe I could modify the pattern some, and still like the result? So I marked all the ties that conformed with the rule:

Started to take out/put in ties in the possible positions... this was the best result I could come up with:

Would I weave this? No, but then, I am on a countermarche...

Compare it to my starting point:

I tried various other even tieups with much the same results, and in the end I decided that there is a good reason the pulleys are called "dräll" pulleys: they are excellent for two-block "opposite" structures! For all the others, there are countermarche looms...

Labels:

counterbalance looms,

dräll,

twill,

weave construction

21/05/2016

All you need to know about counterbalance looms?

As it is continually said that it is "impossible" to weave "unbalanced" sheds on counterbalance looms, I decided to make an illustrated guide to why it is actually perfectly do-able...

So, now there are two new pages on my website - one about how an ordinary Swe style 4-shaft CB loom with horses works, and another one about how dräll pulleys work, and what they can be used for.

Labels:

counterbalance looms,

looms,

weave construction

15/12/2014

The never-ending story

or: yet some more pulleys

Considering I am a countermarche convert since first I tried one, it is interesting how odd counterbalance set-ups seem to come my way...

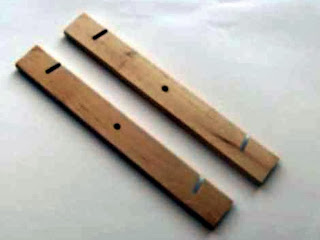

Have been to a flea-market again. Found some CB pulleys again. This time a pair of homemade(?) two-level type:

They look almost like the standard type, still sold:

- with the exception of all the extra holes.

They must be there for a reason, but which? To change the position of the pulleys? But if so, why?

DH speculated it was to be able to maximize the shed size.

But would that even be true, as, after all, the size/length of the horses (and their cords) must be so much easier to change than having to fiddle with a peg?

(Also considering the height of the reeds "way back when" - my old reeds measure between 5 and 8 cm, so theoretical shed size cannot have been a big question :-)

I left them at the flea market. Should anybody be interested, they will probably still be there for some time... light-weight and easy to pack. (Price? Don't know, unmarked) - come to think of it, there were also a couple of old-fashioned dräll pulleys, more or less like these

though I can't remember if 3, 4 or 5 levels. Again unmarked, but perhaps I could get a good price for both?

(If they are to be sent by post, they will probably not reach anywhere before x-mas)

Considering I am a countermarche convert since first I tried one, it is interesting how odd counterbalance set-ups seem to come my way...

Have been to a flea-market again. Found some CB pulleys again. This time a pair of homemade(?) two-level type:

They look almost like the standard type, still sold:

- with the exception of all the extra holes.

They must be there for a reason, but which? To change the position of the pulleys? But if so, why?

DH speculated it was to be able to maximize the shed size.

But would that even be true, as, after all, the size/length of the horses (and their cords) must be so much easier to change than having to fiddle with a peg?

(Also considering the height of the reeds "way back when" - my old reeds measure between 5 and 8 cm, so theoretical shed size cannot have been a big question :-)

I left them at the flea market. Should anybody be interested, they will probably still be there for some time... light-weight and easy to pack. (Price? Don't know, unmarked) - come to think of it, there were also a couple of old-fashioned dräll pulleys, more or less like these

though I can't remember if 3, 4 or 5 levels. Again unmarked, but perhaps I could get a good price for both?

(If they are to be sent by post, they will probably not reach anywhere before x-mas)

31/07/2014

Dräll pulleys, another configuration

Yet another way to combine/mount pulleys for multishaft weaving:

I had never seen dräll pulleys like these before. (Spotted at a flea market near me, and way too expensive just "for fun")

I think this way to mount them is asking for trouble: if the cross piece from which they are hung doesn't have the correct size, they will tilt. Even with the "correct" cross piece, there will be a completely un-necessary force on the axle.

No, if ever I go for dräll pulleys again, I think I will stay with the vertical arrangement.

I had never seen dräll pulleys like these before. (Spotted at a flea market near me, and way too expensive just "for fun")

I think this way to mount them is asking for trouble: if the cross piece from which they are hung doesn't have the correct size, they will tilt. Even with the "correct" cross piece, there will be a completely un-necessary force on the axle.

No, if ever I go for dräll pulleys again, I think I will stay with the vertical arrangement.

08/06/2014

Multishaft counterbalance looms

...and some "different" configurations for the tie-up of horses.

I stumbled on Sue's blog the other day, and found some astonishing CB pictures.

I don't know Sue, but she has informative and picture-heavy posts about travels in India and Turkey. Because of the many pictures I will first link directly to the one I found most interesting, and then to the actual post. All links will open I new windows.

This picture is from India.

I have never seen this arrangement before: the horses are at the top, the pulleys underneath. It makes great sense, though! Here is the blog post.

Now two pictures from Turkey. This one shows only 4 shafts, but it also shows that our obsession with measurements probably is overkill...

Blog post here

Sue writes that this loom has 24 shafts (but only 12 treadles). What can we say? That we are hopeless wimps?

Blog post (with a couple more pictures of the same loom) here

25/02/2014

Once spotted...

To think that I hadn't seen this kind of double pulleys (or, not consciously, anyway) until a couple of months ago... now I see them everywhere.

Spotted at a flea market not far from here:

As (again) they were without companions, I left them for someone else to play with.

(And Jean, if you read this, the strange shaft-ties: I have given up on that, until I can get to the museum myself. They keep giving me the wrong references - )

04/12/2013

The last about double pulleys

For now, anyway :-)

First of all: I now own one double pulley! It was there, just beside the double flyer spinning wheel - it rather seemed like a "double" day. Until I asked for the other pulley... the dealer didn't even understand the question: why should he have a pair?

Anyway, it followed me home (even though the pulleys won't turn):

In the last post about double pulleys I wondered about Grenander's sentence "[...]with two pulleys on two axles on the same level [...]"

Jean graciously sent me a picture of this kind of double pulley(s):

Thanks, Jean - I had never seen such pulleys before, but apparently they existed even here.

Anyway, when I unearthed my folding CB to ready it for a demo, I decided to try to rig a "double pulley" simulation, to see if it would work with the crossed cord tie-up.

I thought I would just tie four cords over the castle, like this:

Half an hour later I decided I wasn't very interested, after all. (IOW, I couldn't get it to balance/work...) The horses went back on, and the demo went considerably better that it would have with the crossed cords...

Conclusion: hooray for countermarches!

First of all: I now own one double pulley! It was there, just beside the double flyer spinning wheel - it rather seemed like a "double" day. Until I asked for the other pulley... the dealer didn't even understand the question: why should he have a pair?

Anyway, it followed me home (even though the pulleys won't turn):

In the last post about double pulleys I wondered about Grenander's sentence "[...]with two pulleys on two axles on the same level [...]"

Jean graciously sent me a picture of this kind of double pulley(s):

Thanks, Jean - I had never seen such pulleys before, but apparently they existed even here.

Anyway, when I unearthed my folding CB to ready it for a demo, I decided to try to rig a "double pulley" simulation, to see if it would work with the crossed cord tie-up.

I thought I would just tie four cords over the castle, like this:

Half an hour later I decided I wasn't very interested, after all. (IOW, I couldn't get it to balance/work...) The horses went back on, and the demo went considerably better that it would have with the crossed cords...

Conclusion: hooray for countermarches!

15/11/2013

On double pulleys and no horses (warning, long)

(I should have been sewing, but the pins are too fiddly for the wrenched wrist. So I have been reading, instead.)

I started with Gertrud Grenander-Nyberg's Lanthemmens vävstolar (1974, ISBN 91-7108-076-7). On pages 287 f she writes about double pulleys (my translation; my comments in italics):

For plain weave, threaded on four shafts, there was a pulley type seldom used nowadays, namely two pulleys mounted on the same axle. The pulleys can be of different size. For the tying, the outer shafts were tied with the cord over the bigger pulley, which made the shaft tieup clearer (simpler?)

Important words here: CAN be of diff size. In most (all?) pictures I've seen they have been of the same (or so near the same as possible) size. (Had they been different size, they could have been called "horizontal dräll pulleys"? Has anyone seen an example of that (ie with more than two pulleys)? Edit: here.

The Finnish textile technician Helvi Pyysalo has showed that two pulleys on the same level can be used for four-shaft even-sided twill by connecting shafts one and three over one pulley and shafts two and four over the other pulley.

With this method follows that, when the shafts are lowered in pairs in four different combinations, the cords on both pulleys will move, which is (recommended, necessary? - "good") to get a clear shed.

I don't understand that: does she say that for EVERY shed on a CB loom "both cords should move"? If so: why?? Or what is it I don't understand here? With one pulley and horses that is not always the case, but sheds can be good anyway.

This can happen not only with two pulleys on two axles on the same level but also with the pulleys mounted on the same axle like on a double pulley.

Is there a difference in appearance in the two described above? (for "double pulley" she uses the Swedish "parblock", so in the text there is a distinction between the two types here.) ETA: see picture here.

It is likely that the double pulleys were used in this fashion in older times for weaving even-sided twill. With the pulleys on the same level the upper tieup was lower than if it was accomplished with several tools on different levels. Double pulleys were therefore an advantage when using the oldest looms which have low castles. This can be an explanation to the numerous double pulleys from the older times.

Nowadays, for four shafts, usually only one of the pulleys is used in combination with horses.

Same author, 25 years later, in Linnelärft i Ångermanland (2001, ISBN 91-7108-480-0), has slightly changed her ideas.

Background, about "premielärft" - roughly "prime quality linen cloth": in 18th century the "powers" divided the country and decided Ångermanland was the region to grow flax and (spin and) weave linen. To make the people more enthusiastic about it, certain standards were set, and those who fulfilled them got extra pay.

Anyway. According to Grenander, weavers of prime cloth were specialists, using special looms. Those looms were often shallower than "allround" looms - sources from the time state that an allround loom was usually about 2 1/2 aln (about 5 ft), while linen looms were only 2 aln (4 ft).

The reasoning behind that is (apart from the fact that German linen looms often were shallow) that the "free" warp is shorter, and therefore less exposed to wear (p 99).

Something I don't understand here: as linen is not elastic, shouldn't it benefit from a longer "free" warp, by distributing the stretch over a longer section?

(She goes on to say that plain weave needs less loom-depth than multi-shafted cloth, which is of course true.)

She also thinks that the double pulleys, at least those with short uprights, were used primarily by these specialist weavers.

(To me it is not clear exactly how she came to that conclusion.)

On p 103 she writes that, because of the fineness of the prime cloth, the warps had to be distributed over four shafts, and therefore the double pulleys were "the most efficient". Thus looms with double pulleys were, together with very fine reeds, the most typical tools of a "prime" weaver.

I'm still unsure of why double pulleys are "the most efficient"...

Anyway, it is apparent that she has changed her mind over the 25 years between her thesis and her last book - from thinking that double pulleys were, in effect, "old-fashioned", to thinking they were the mark of a specialist.

Just for curiosity: "prime linens" came i 8 classes. They were (at least most of them) 1 1/2 aln (3 ft, or 88 cm) wide.

For class 1 there were 2720-2920 ends ( or 30-32 ends/cm); for class 8 (the finest) there were 4120-4 320 ends (or 45-48 ends/cm). (from Uppfinningarnas bok, band 6 from 1873.

And this, my friends, was all handspun singles!

I started with Gertrud Grenander-Nyberg's Lanthemmens vävstolar (1974, ISBN 91-7108-076-7). On pages 287 f she writes about double pulleys (my translation; my comments in italics):

For plain weave, threaded on four shafts, there was a pulley type seldom used nowadays, namely two pulleys mounted on the same axle. The pulleys can be of different size. For the tying, the outer shafts were tied with the cord over the bigger pulley, which made the shaft tieup clearer (simpler?)

Important words here: CAN be of diff size. In most (all?) pictures I've seen they have been of the same (or so near the same as possible) size. (Had they been different size, they could have been called "horizontal dräll pulleys"? Has anyone seen an example of that (ie with more than two pulleys)? Edit: here.

The Finnish textile technician Helvi Pyysalo has showed that two pulleys on the same level can be used for four-shaft even-sided twill by connecting shafts one and three over one pulley and shafts two and four over the other pulley.

With this method follows that, when the shafts are lowered in pairs in four different combinations, the cords on both pulleys will move, which is (recommended, necessary? - "good") to get a clear shed.

I don't understand that: does she say that for EVERY shed on a CB loom "both cords should move"? If so: why?? Or what is it I don't understand here? With one pulley and horses that is not always the case, but sheds can be good anyway.

This can happen not only with two pulleys on two axles on the same level but also with the pulleys mounted on the same axle like on a double pulley.

Is there a difference in appearance in the two described above? (for "double pulley" she uses the Swedish "parblock", so in the text there is a distinction between the two types here.) ETA: see picture here.

It is likely that the double pulleys were used in this fashion in older times for weaving even-sided twill. With the pulleys on the same level the upper tieup was lower than if it was accomplished with several tools on different levels. Double pulleys were therefore an advantage when using the oldest looms which have low castles. This can be an explanation to the numerous double pulleys from the older times.

Nowadays, for four shafts, usually only one of the pulleys is used in combination with horses.

Same author, 25 years later, in Linnelärft i Ångermanland (2001, ISBN 91-7108-480-0), has slightly changed her ideas.

Background, about "premielärft" - roughly "prime quality linen cloth": in 18th century the "powers" divided the country and decided Ångermanland was the region to grow flax and (spin and) weave linen. To make the people more enthusiastic about it, certain standards were set, and those who fulfilled them got extra pay.

Anyway. According to Grenander, weavers of prime cloth were specialists, using special looms. Those looms were often shallower than "allround" looms - sources from the time state that an allround loom was usually about 2 1/2 aln (about 5 ft), while linen looms were only 2 aln (4 ft).

The reasoning behind that is (apart from the fact that German linen looms often were shallow) that the "free" warp is shorter, and therefore less exposed to wear (p 99).

Something I don't understand here: as linen is not elastic, shouldn't it benefit from a longer "free" warp, by distributing the stretch over a longer section?

(She goes on to say that plain weave needs less loom-depth than multi-shafted cloth, which is of course true.)

She also thinks that the double pulleys, at least those with short uprights, were used primarily by these specialist weavers.

(To me it is not clear exactly how she came to that conclusion.)

On p 103 she writes that, because of the fineness of the prime cloth, the warps had to be distributed over four shafts, and therefore the double pulleys were "the most efficient". Thus looms with double pulleys were, together with very fine reeds, the most typical tools of a "prime" weaver.

I'm still unsure of why double pulleys are "the most efficient"...

Anyway, it is apparent that she has changed her mind over the 25 years between her thesis and her last book - from thinking that double pulleys were, in effect, "old-fashioned", to thinking they were the mark of a specialist.

Just for curiosity: "prime linens" came i 8 classes. They were (at least most of them) 1 1/2 aln (3 ft, or 88 cm) wide.

For class 1 there were 2720-2920 ends ( or 30-32 ends/cm); for class 8 (the finest) there were 4120-4 320 ends (or 45-48 ends/cm). (from Uppfinningarnas bok, band 6 from 1873.

And this, my friends, was all handspun singles!

Labels:

counterbalance looms,

curiosities,

looms

07/11/2013

More about horses

In Sweden, everybody knows how to tie the horses. They "must" be parallel, but opposite - like this:

(well, they can be the other way around,too)

Then I found a picture on the 'net - a picture that can't be copied, only linked to.

From what I can see, the horses are tied in a pattern I have never seen before:

Let's see if this gives the right photo:

This photo of Museo-Laboratorio di tessitura a mano Giuditta Brozzetti is courtesy of TripAdvisor.

Or is she using just three shafts? I can't see the fourth, but it also does not look like the horses are tied two-to-one-shaft...

If they are, they still look like a "different" style.

This is how three shafts "should" be tied, according to Swe traditions:

Either tie one shaft to both ends of one horse, the other horse to the two other shafts (works best, IMO), or tie both horses to the middle shaft.

(well, they can be the other way around,too)

Then I found a picture on the 'net - a picture that can't be copied, only linked to.

From what I can see, the horses are tied in a pattern I have never seen before:

Let's see if this gives the right photo:

This photo of Museo-Laboratorio di tessitura a mano Giuditta Brozzetti is courtesy of TripAdvisor.

Or is she using just three shafts? I can't see the fourth, but it also does not look like the horses are tied two-to-one-shaft...

If they are, they still look like a "different" style.

This is how three shafts "should" be tied, according to Swe traditions:

Either tie one shaft to both ends of one horse, the other horse to the two other shafts (works best, IMO), or tie both horses to the middle shaft.

30/10/2013

Styles of horses and pulleys

I wrote this post on Monday, and the instant I was going to click "publish" the electricity vanished. We were powerless for about 20 hours. Ironically, both "before" us (on the power line) and "after" us ("us", here, means some 25-39 houses along the road) did have electricity, except for 15 minutes. BUT: it is our part of the power lines that is buried, "to avoid power cuts in the future". Go figure!

The best laid plans can be wrecked in an instant - . More than a week ago, I fell and wrenched my right wrist and my left ankle (and got several sore spots in between). It could have been a lot worse, but I still can’t lift anything heavier than a coffee mug...

So I decided to trawl the 'net for different types of horses-and-pulleys. Simple as they are, there are a lot of different styles "out there".

A "horse" is, in principle, no more than a dowel with a hole in the middle and a slit, knob or something to stop the shaft-connectin cords from falling off.. A horse should be about the length of the heddles used – or longer. (On old looms the horses are often quite a bit longer.)

Some are quite ornate, some are strictly utilitarian.

These two styles are lifted from Blomqvist/Nordiska (made by Glimåkra) and AK:s snickeri (aka Öxabäck), respectively:

However, no horses function without a pulley, over which they are connected. Pulleys can be small(ish) and connected to the loom just by cords, or they can be bigger, having a hole through which the top cross-member of the loom can pass.

Glimåkra used to use the free-hanging pulleys – this picture is lifted from a for-sale ad on the 'net. I have no idea how old this loom is – in fact, I don’t know that it is a Glimåkra, but that’s what the seller says:

Some other examples, most of them lifted from ads:

A small "no-name", no age given (50-ies, 60-ies?)

Probavly a very old loom, which has some curious pulleys (they are double, both the same size. What is the other pulley for?). The shafts hanging every which-way is typical of CB looms without a warp. Unless they are stabilized with a shaft-holder, of course.

These pictures are from Madesjö museum (I have written about it before)

From the same trip, a five-shaft pulley used as if it were a "normal" one:

(To use it for 5 shafts, the fifth is generally placed at the back, with a cord from the shaft to the hole that I nearly point at. It can be tricky to get it balanced...)

This is just a pulley, again from an ad. The seller just calls it "a detail from an antique loom", and wants to sell them one by one. (Pulleys always come in pairs, horses always in, hm, "foursomes"(?))

(There is a storm brewing outside - let's hope it will not fell too many trees and cut the power, like the one in '05. But the windows are starting to rattle...)

The best laid plans can be wrecked in an instant - . More than a week ago, I fell and wrenched my right wrist and my left ankle (and got several sore spots in between). It could have been a lot worse, but I still can’t lift anything heavier than a coffee mug...

So I decided to trawl the 'net for different types of horses-and-pulleys. Simple as they are, there are a lot of different styles "out there".

A "horse" is, in principle, no more than a dowel with a hole in the middle and a slit, knob or something to stop the shaft-connectin cords from falling off.. A horse should be about the length of the heddles used – or longer. (On old looms the horses are often quite a bit longer.)

Some are quite ornate, some are strictly utilitarian.

These two styles are lifted from Blomqvist/Nordiska (made by Glimåkra) and AK:s snickeri (aka Öxabäck), respectively:

However, no horses function without a pulley, over which they are connected. Pulleys can be small(ish) and connected to the loom just by cords, or they can be bigger, having a hole through which the top cross-member of the loom can pass.

Glimåkra used to use the free-hanging pulleys – this picture is lifted from a for-sale ad on the 'net. I have no idea how old this loom is – in fact, I don’t know that it is a Glimåkra, but that’s what the seller says:

Some other examples, most of them lifted from ads:

A small "no-name", no age given (50-ies, 60-ies?)

Probavly a very old loom, which has some curious pulleys (they are double, both the same size. What is the other pulley for?). The shafts hanging every which-way is typical of CB looms without a warp. Unless they are stabilized with a shaft-holder, of course.

These pictures are from Madesjö museum (I have written about it before)

From the same trip, a five-shaft pulley used as if it were a "normal" one:

(To use it for 5 shafts, the fifth is generally placed at the back, with a cord from the shaft to the hole that I nearly point at. It can be tricky to get it balanced...)

This is just a pulley, again from an ad. The seller just calls it "a detail from an antique loom", and wants to sell them one by one. (Pulleys always come in pairs, horses always in, hm, "foursomes"(?))

(There is a storm brewing outside - let's hope it will not fell too many trees and cut the power, like the one in '05. But the windows are starting to rattle...)

14/07/2012

Another trip

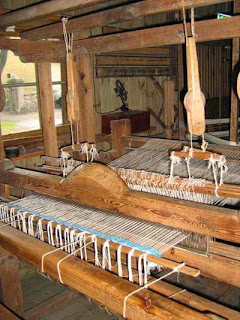

Yesterday I went to visit with Monica at Madesjö museum, where she sometimes weaves.

We admired the huge loom - look at this fantastic beater, for instance:

(We also failed to understand some of it’s ... features?. But we agreed that we, both of us, do not like a sloping warp. Whatever the old books say, we both prefer our warps to be horizontal!)

After that, we went on to her guild room, with a gazillion looms, many of which had (shaft) draw attachments. I was surprised to see the drawlooms had no (or very short) warp extensions.

BUT... there was this fantastic old loom (which has me in it):

Look at the details:

It has five-shaft pulleys:

I liked the nice pattern the height-adjustments on the beater swords:

And... to prove it: here is Monica herself, in the middle of all the looms:

We admired the huge loom - look at this fantastic beater, for instance:

(We also failed to understand some of it’s ... features?. But we agreed that we, both of us, do not like a sloping warp. Whatever the old books say, we both prefer our warps to be horizontal!)

After that, we went on to her guild room, with a gazillion looms, many of which had (shaft) draw attachments. I was surprised to see the drawlooms had no (or very short) warp extensions.

BUT... there was this fantastic old loom (which has me in it):

Look at the details:

It has five-shaft pulleys:

I liked the nice pattern the height-adjustments on the beater swords:

And... to prove it: here is Monica herself, in the middle of all the looms:

03/03/2012

Oooops – I forgot!

Tomorrow is the "culture day" – how could I forget?

What to do? What to bring? And it is almost 4 already...

Fish out the old Göta – not my favourite, but in many ways easier to handle than the table loom.

Not many heddles – and not much time; so why not weave for an experiment...

but this time in wool-only, hoping for an interesting result

Unfolded Göta at the kitchen table, helpers in attendance:

A while later: weaving started, waiting for tomorrow

Watch this space!

What to do? What to bring? And it is almost 4 already...

Fish out the old Göta – not my favourite, but in many ways easier to handle than the table loom.

Not many heddles – and not much time; so why not weave for an experiment...

but this time in wool-only, hoping for an interesting result

Unfolded Göta at the kitchen table, helpers in attendance:

A while later: weaving started, waiting for tomorrow

Watch this space!

Labels:

counterbalance looms,

double layers,

false double weave,

looms

19/12/2011

Thoughts about looms

No weaving going on hereabouts, but lots of weaving-related tinking.

I have spent some time deciphering old-ish handwritten drafts. This has made me wonder about lots of things...

One of them is: can we draw any conclusions about looms used from drafts/tie-up used?

The most standard of all Swedish looms is the 4-shaft counterbalance, with one pulley and two horses (on each side of the loom, of course!). (Horses - in Swedish those are often called "nicke-pinnar", "nodding dowels". I don't know any other English word than horse - pls help?) Lamms have been used for a relatively long time. No lamms did not necessarily mean "direct tie-up" - it was pefectly possible to tie more than one shaft to one treadle. To prevent the shafts from moving sideways, one could use a ring of some sort (a piece of cow's horn, it says in one book) to keep the treadle cords together.

Countermarches were is use in the early 1800s, but how common were they?

The most common (I think) way to add more shafts was to use "lunor" - ie two-level pulleys (left) or dräll-pulleys:

From all the extras that came with my loom I think that, maybe, a 3-level pulley was used with horses, thus giving the loom a capacity to use 12 shafts, like this:

(Seen from the side: 2 shafts connected by horses to one cord that goes over the pulley and down on the other side - thus 6 shafts on the back of the pulley-contraption, 6 (not pictured) in front of it)

I have used such a set-up a couple of times, and it is... - well, let's say it can be done, but it takes lots of patience to get the whole thing balanced. However, I fully inderstand why one can prefer to use dräll pulleys (or countermarche) instead.

Dräll pulleys have one drawback: the tie-up has to be on opposites: what goes down in the one end must come up in the other:

So: can I draw any conclusions as to the type of loom was used, when I find several 8-shaft "not-opposite" tieups in one manuscript? As the majority of weaves are 4-shaft and of many different types, I'm not seeing the legacy of a specialist weaver (I think). There are a couple of opposite tie-ups, and as many not-opposites.

Am I seeing a weaver with lots of patience, or one with a countermarche? (From all the extras that came with my loom: maybe I'm seeing a weaver with a loom that is on its way to be upgraded?)

I asked my guildmates, some of whom have learned to weave 50 years ago, (then) using their (grand-)mother's loom. They all believed in the two-or-more-level pulleys, possibly with elastics to help balancing.

Any thoughts?

I have spent some time deciphering old-ish handwritten drafts. This has made me wonder about lots of things...

One of them is: can we draw any conclusions about looms used from drafts/tie-up used?

The most standard of all Swedish looms is the 4-shaft counterbalance, with one pulley and two horses (on each side of the loom, of course!). (Horses - in Swedish those are often called "nicke-pinnar", "nodding dowels". I don't know any other English word than horse - pls help?) Lamms have been used for a relatively long time. No lamms did not necessarily mean "direct tie-up" - it was pefectly possible to tie more than one shaft to one treadle. To prevent the shafts from moving sideways, one could use a ring of some sort (a piece of cow's horn, it says in one book) to keep the treadle cords together.

Countermarches were is use in the early 1800s, but how common were they?

The most common (I think) way to add more shafts was to use "lunor" - ie two-level pulleys (left) or dräll-pulleys:

From all the extras that came with my loom I think that, maybe, a 3-level pulley was used with horses, thus giving the loom a capacity to use 12 shafts, like this:

(Seen from the side: 2 shafts connected by horses to one cord that goes over the pulley and down on the other side - thus 6 shafts on the back of the pulley-contraption, 6 (not pictured) in front of it)

I have used such a set-up a couple of times, and it is... - well, let's say it can be done, but it takes lots of patience to get the whole thing balanced. However, I fully inderstand why one can prefer to use dräll pulleys (or countermarche) instead.

Dräll pulleys have one drawback: the tie-up has to be on opposites: what goes down in the one end must come up in the other:

So: can I draw any conclusions as to the type of loom was used, when I find several 8-shaft "not-opposite" tieups in one manuscript? As the majority of weaves are 4-shaft and of many different types, I'm not seeing the legacy of a specialist weaver (I think). There are a couple of opposite tie-ups, and as many not-opposites.

Am I seeing a weaver with lots of patience, or one with a countermarche? (From all the extras that came with my loom: maybe I'm seeing a weaver with a loom that is on its way to be upgraded?)

I asked my guildmates, some of whom have learned to weave 50 years ago, (then) using their (grand-)mother's loom. They all believed in the two-or-more-level pulleys, possibly with elastics to help balancing.

Any thoughts?

Labels:

counterbalance looms,

countermarche looms,

looms,

Maja,

tools,

weave construction

Subscribe to:

Posts (Atom)