My very busy half-year is (hopefully) soon coming to an end: in October my mother (97) moved to a so called service apartment.

"Down-sizing", anyone?

I have been carting things here and there, to her new place and to me (and some to second-hand and the dump, too). But now I can see the end of all this – her old apartment is going on the market in a couple of weeks. (After I have taken one last load down here... - faamous lsat words?)

Last week I came home with a well-travelled suitcase, containing a jacket, an experimental moebius scarf (made by me) and some small yardage pieces (woven by her) – also some glass pieces for our growing museum, and some for re-homing.

(I really like how the back of the hood came out!)

Also, plans start to emerge for the Event of the Year: VÄV2017, this time at a place near me.

Oh yes – what happened in Bergdala, Sweden last Friday: grey/rainy weather with icy roads, the snowdrops got visible again after the rain, the assiettes got re-homed and the service workshop ordered a new part for my new computer. Even if the wind sometimes was hard, there were no earth-shaking events (but the aspen across the lane still looks like it will fall with the smallest gust of wind).

So there!

Showing posts with label curiosities. Show all posts

Showing posts with label curiosities. Show all posts

20/02/2017

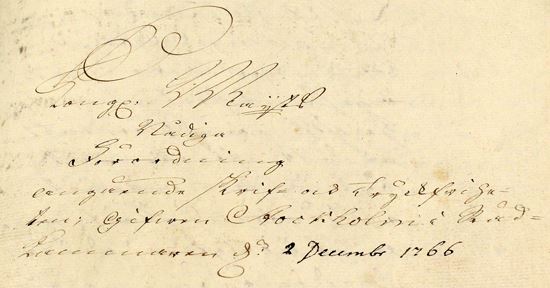

02/12/2016

Happy birthday!

Today the world's oldest Freedom of the Press Regulation is 250 years old.

And what's more: it is the Swedish Freedom of the Press law!

Read more at https://frittord250.se/!

This post ought to be labeled as "essentials", but will instead get the label "curiosities".

To make some sort of textile connexion, here are some text messages:

And what's more: it is the Swedish Freedom of the Press law!

Read more at https://frittord250.se/!

This post ought to be labeled as "essentials", but will instead get the label "curiosities".

To make some sort of textile connexion, here are some text messages:

05/07/2016

Busy, but (still) not weaving

What with going up and down to Town (aka Stockholm) a lot, and getting the Glass museum ready for the tourist season, I haven't had much time for textiles.

(but the Glass museum site is now "on par" - ie all pages exist in both Swedish and English - and there is a g**le translate option both on the website and on the blog - feel free to visit!)

(EDIT: I just checked the translation of today's blog post... ACKKK! g**le translate isn't very helpful when it comes to oddities... is there a way I can convince you that it IS intelligible in Swe?!?)

However, this morning I found this:

which shows that that (the not-weaving) is not necessarily a problem...

(a few comments:

- "damastduk"? ok, so it says "paper" in a sort-of-backwards way, but... How will non-textile-y ppl understand what a damask (table)cloth can be, in some years time?

- "damast"? the pattern (not visible in the picture) shows a typical 4-block (possibly only 2-block... didn't open the package) true dräll* - for Swe weavers, damask is a considerably more complex pattern, usually achieved with the help of a drawloom...)

* "about dräll and other patterns"

(but the Glass museum site is now "on par" - ie all pages exist in both Swedish and English - and there is a g**le translate option both on the website and on the blog - feel free to visit!)

(EDIT: I just checked the translation of today's blog post... ACKKK! g**le translate isn't very helpful when it comes to oddities... is there a way I can convince you that it IS intelligible in Swe?!?)

However, this morning I found this:

which shows that that (the not-weaving) is not necessarily a problem...

(a few comments:

- "damastduk"? ok, so it says "paper" in a sort-of-backwards way, but... How will non-textile-y ppl understand what a damask (table)cloth can be, in some years time?

- "damast"? the pattern (not visible in the picture) shows a typical 4-block (possibly only 2-block... didn't open the package) true dräll* - for Swe weavers, damask is a considerably more complex pattern, usually achieved with the help of a drawloom...)

* "about dräll and other patterns"

Labels:

cultural differences,

curiosities,

dräll,

drawlooms

09/04/2016

Announcing:

my new, ok a new, website, of which I happen to be responsible: Bergdala glastekniska museum.

Most pages are still in Swedish only, but some have been translated. The link takes you to the start page in English - for Swedish, click the "på svenska" in the upper part of the navigation column.

As my glass English is not the best (I have been using this page a lot, but what do I know...?!?), I hope you can help me out... all and any thoughts and comments are welcome!

Due to other concentration-consuming activities, I totally forgot about "April spools day" this year.

So, a bit late, a picture to combine spools and glass:

This is a plate used for pantographing a pattern onto several (in our case 24) glasses at the same time, making them ready for acid etching.

(On the off chance: should anybody "out there" recognize the pattern, I would very much like to know "all": name, designer, time, picture(s)...)

Most pages are still in Swedish only, but some have been translated. The link takes you to the start page in English - for Swedish, click the "på svenska" in the upper part of the navigation column.

As my glass English is not the best (I have been using this page a lot, but what do I know...?!?), I hope you can help me out... all and any thoughts and comments are welcome!

Due to other concentration-consuming activities, I totally forgot about "April spools day" this year.

So, a bit late, a picture to combine spools and glass:

This is a plate used for pantographing a pattern onto several (in our case 24) glasses at the same time, making them ready for acid etching.

(On the off chance: should anybody "out there" recognize the pattern, I would very much like to know "all": name, designer, time, picture(s)...)

12/09/2015

Too many hats

Where has summer gone? And what have I been doing?

I have had too many hats, and only one head, that's what.

We are trying to organize a fibre-optic net locally (this is what living in the boondocks means - having to "fix" whatever we want ourselves... sometimes it is ok, sometimes less so);

we (a slightly different "we") are trying to organize a small museum for glass, not exactly technology, but showing old-ish machines, such as a manual press, a pantograph and... (read more here, only in Swedish);

I have been working on a couple of web sites - and I have had big problems with my web access (up/downloads of files bigger than a couple of k tended to die).

I have also washed my old kilim rug. To do this I had to invent a drying rack, as this (like all rugs) get very heavy when wet. My contraption may not work for wider rugs, but here it is, anyway:

take two ladders and some string, tie them together along the long edges (short strings on top, longer at the bottom), add one or more pieces of gutter upside down:

Next will be a stint of sewing, and, perhaps, more blogging.

04/05/2015

20/04/2015

The story of the little warp that grew

This happened many years ago (maybe in the late 80-ies?).

A weaving guild I was associated with decided to do a vadmal project. I don't remember how many participants, or how many warps. But I do remember there was a lot of research done, and many discussions with spinning mills (I think we had two or three "custom" mills in Sweden at that time). It was decided we should order our yarns from Solkustens spinneri (at that time they were located outside Oskarshamn). So we ordered "warp spun" singles in white, also some ombré yarn (grey -> white -> grey).

All warps were wound 20 metres long.

The cloth from the loom I wove on came off as 22 metres. Plus thrums, and the dimensional loss we all learn to estimate at some 10%.

No, it wasn't mis-warped; the yarn had stretched. (IIRC, most cloths came out slightly longer than the warp length.)

It all ended happily: we went to a hammer mill deep in the woods, we hammered for hours (and hours), came home and made coats and other clothing.

- the ombré users noted that the white and grey portions had shrunk differently and pressed for hours, in hope to flatten their fabric.

All of us noted that the selvages were longer than the rest of the fabric. Some of us found ways to utilize the flaring edges, others tried to press them flat.

(Many years later, I did it again, with some other friends, different yarns, different mill - read about the vadmal adventure here (in Swedish here).

The flaring edges from my first experience made me fold the fabric in a different way this time, which worked: the edges came out nearly the same length as the rest, but instead we got "in-and-out" waves.)

So what has this to do with anything?

Not a lot.

But when I finally cut off this fan-reed fabric, it was a little shy of 6 metres (and I might have had maybe 50 cms more).

Considering I thought I had warped around 4 metres, the result made me remember the vadmal warp. In this case I guess I made two turns (and then some) on the warping mill instead of one turn (and then some).

22/03/2015

A little sewing on the side

(but don't tell anybody that the very sloppy-looking stitching is mine, please!)

"Can you make a cover for an inflatable beach ball? It needs to be mainly blue, and have patches in several colours."

"Er??? I mean yes, I suppose so, but what...?"

"It will represent how much each of us humans would have at our disposal, should the earth (resources) be fairly divided."

So I looked in the "eyes", found some blue, green, yellow, red and black acetate lining fabric (and a couple of other scraps). The "client" made the pattern (it was his beach ball, after all), and I sewed.

It was fiddly to appliqué the patches (I'm using the word quite loosely, here - they are merely basted on), and it turned out the ball was a tad too big, thus the not-very-sightly gusset-y thing. But it is ready for play tomorrow, which was one of the wishes from the client.

(The blue is for the sea, red is for "unusable" (mountains and wasteland), yellow is for savannah, green for forests, the blue-with-plaid is for pasture and the black is for fertile land. There are two of each "non-fertile" patch. Each human has a total of 5 and a half football fields, which is what all the patches combined sum up to, I am told.)

13/02/2015

The un-trimmed "daff"

As there is more warp on the loom, and as one never can know what happens with the weather (and thus with the outdoor daffs):

I guess it will be trimmed some, before the whole thing can be called finished :-)

I guess it will be trimmed some, before the whole thing can be called finished :-)

Labels:

curiosities,

daffodil&snowdrop,

false double weave

12/01/2015

I'm sure some of you have seen this remarkable machine before. I know I have, but I had forgot the name of the creator. So when I happened to stumble on it again - :

The picture comes from class sculptor Andy Paiko's website, where one can also find a video of a woman spinning wool on it. There are also more pics of the spinning wheel - and don't forget to look at his other creations!

Isn't it fantastic!?!

And to think I live in "the kingdom of Crystal"... gives me ideas, it does!

The picture comes from class sculptor Andy Paiko's website, where one can also find a video of a woman spinning wool on it. There are also more pics of the spinning wheel - and don't forget to look at his other creations!

Isn't it fantastic!?!

And to think I live in "the kingdom of Crystal"... gives me ideas, it does!

17/12/2014

Local newspapers

Who said that local newspapers mostly contain local gossip?

Well, at least that is what I have always thought. So today I went to the local archive to read Nya Wexiö-Bladet for 1847 - the year that Mlle Granberg was touring the county giving classes in double-spinning.

I anticipated coming home with lot lots of "gossipy" information, such as Joahnna Månstdotter and Lina Andersson did attend the class in Lenhovda, and after only a week were able to spin 3 "pops" (knäpp) weighing only 2 "lod", or somesuch. Hopefully I would find advertisements and, and...

But. No such luck. In fact, almost no luck at all.

I found a few names, but those all belonged to remarkable spinsters from before the classes.

I found no advertisements at all (for things relevant, such as the classes themselves, spinning wheels, "modern" hackles...). Also I found nothing about the actual classes, not even the slightest mention!

What I did find was a kind of "morality", in the form of a conversation between "Mrs X", "the girl" and "the uncle":

Mrs X didn't want to send her maid to the spinning school, but the girl (niece of Mrs X, in fact) was going, because the uncle had said it was a Good Thing To Do.

Enters said uncle, who proceeds to tell the Ladies why [double-flyer] spinning school was such a good idea: it was "ancient" (had been used in Brabant for over 100 years - imagine that!); it would give work to paupers [my comment: why couldn't they get work spinning on a normal wheel, if spinsters were so sought-after?]; he gave a long lecture about the economics [interesting, but it will take some time until I can untangle all the various measurements used]; last, but not least: the Ladies ought to resume the responsibility of being Role Models.

Nearing the end of the economic lecture, Mrs Y enters. She gets all interested, 'cos that would mean she could turn away beggars without any remorse. Mrs X is nicer, she doesn't like to turn away hungry women without giving them something to eat.

The girl is excited, says she wants to go. [But that was her intention from the beginning]

This was quite a long article, but it ended without any mention at all about how to enrol, who was organizing the event(s), when and where they were to take place.

(Ok, so there might have been mentions I didn't see, but if so, it was in the middle of the "running text" - no advertisements, no "marketing".)

Maybe it wasn't so strange that (at least) one of them had to be cancelled due to low interest? I have found, in another publication, that four or five *were* held, one of them with more than 20 students. There were students turned away because of lack of double spinning wheels. (If you follow that link, don't tell anybody. Taking pics was allowed; showing them is not. Makes sense?!?)

So here comes a "legitimate" picture:

Labels:

curiosities,

DFW,

double flyer wheel,

spinning,

spinning wheels

05/12/2014

AHA - so that's why...!

Once I wanted to weave with paper yarn, and to that end used one of the old wooden reeds.

After a while, I noticed that the dents were not evenly spaced:

Yesterday I came across the doubleweave portion of Zielinski's "Master weaver" where one can get several suggestions as to how to handle the fold when weaving double width.

(Methinks the first idea is the best: "experiment")

Transcription of the marked section (click, and most might be readable):

"Another method is to have special reeds made with dents growing wider towards the fold. Such reeds of rather old vintage can be found in antique shops. The difficulty here is that regardless of the width of the woven fabric the fold must be always at the edge of the reed, which may result in weaving off the center of the loom, unless the reed can be shifted in the batten at will."

I found that an adorable suggestion, which also might have explained my "variable" wooden reed...

Except it doesn't, of course. The open part wasn't even near one end, and wasn't even near to be systematic, whatever that may mean. And no, there weren't dents missing/fallen out, 'cos they usually show...

Labels:

curiosities,

double layers,

reeds,

tips-and-tricks

28/08/2014

More museum examples

On request from Meg I continued looking in the museum catalogue.

And I found two more "interesting" descriptions:

Weaving reed

Material: Wood, Textile

Technique: Knotted

Function: Dividing the warp

The [weaving] reed sits near the cloth beams [yes, plural - my note] in a weaving loom, directly in front of the shafts. It's function is to divide the threads.

The rectangular reeds consist of a wooden frame, into which thin blades of wood (in one instance metal) are mounted with a textile band.

Weaving shuttle

Material: wood

Technique: carpentered [my dictionary says "carpenter" is a verb, so it must be correct...?]

Function: weaving

Shuttle. A cloth consists of two thread systems, warp and weft. The warp is tensioned during weaving and is crossed at right angles by the weft. With the help of the shuttle, the weft is inserted from side to side between the warp ends. The weft can go over and under the warp ends. With a treadle loom the lifting and lowering of the warp ends is done by the treadles. The shuttle is [quill-shaped?], with a hole in which a dowel is fixed. The weft is fastened around the dowel. One [of the shuttles] is patterned in two places.

In all fairness: at Murberget, they have elected to transcribe the text in the old paper catalogue. These two artefacts have no pictures, but in many instances they show the handwritten paper entry, often from the 1920-1940ies. Here is one example.

(I have often marvelled at what the museum generalists came up with a hundred years ago... but that is another story.)

So, Murberget uses the original texts/descriptions - most other museums do not. I remember looking in the Nordiska museets paper catalogue, and... let me say I can understand why they do not transcribe indiscriminately.

However, what is interesting about yesterday's post is that it is written after 1991. As I recall, there were several books about spinning and spinning wheels out by then, even written by Swedish authors... And even generalists should be able to read?

Now, to cheer us all up, a picture:

The picture comes from here.

Be sure to click the pic to biggify!

And I found two more "interesting" descriptions:

Weaving reed

Material: Wood, Textile

Technique: Knotted

Function: Dividing the warp

The [weaving] reed sits near the cloth beams [yes, plural - my note] in a weaving loom, directly in front of the shafts. It's function is to divide the threads.

The rectangular reeds consist of a wooden frame, into which thin blades of wood (in one instance metal) are mounted with a textile band.

Weaving shuttle

Material: wood

Technique: carpentered [my dictionary says "carpenter" is a verb, so it must be correct...?]

Function: weaving

Shuttle. A cloth consists of two thread systems, warp and weft. The warp is tensioned during weaving and is crossed at right angles by the weft. With the help of the shuttle, the weft is inserted from side to side between the warp ends. The weft can go over and under the warp ends. With a treadle loom the lifting and lowering of the warp ends is done by the treadles. The shuttle is [quill-shaped?], with a hole in which a dowel is fixed. The weft is fastened around the dowel. One [of the shuttles] is patterned in two places.

In all fairness: at Murberget, they have elected to transcribe the text in the old paper catalogue. These two artefacts have no pictures, but in many instances they show the handwritten paper entry, often from the 1920-1940ies. Here is one example.

(I have often marvelled at what the museum generalists came up with a hundred years ago... but that is another story.)

So, Murberget uses the original texts/descriptions - most other museums do not. I remember looking in the Nordiska museets paper catalogue, and... let me say I can understand why they do not transcribe indiscriminately.

However, what is interesting about yesterday's post is that it is written after 1991. As I recall, there were several books about spinning and spinning wheels out by then, even written by Swedish authors... And even generalists should be able to read?

Now, to cheer us all up, a picture:

The picture comes from here.

Be sure to click the pic to biggify!

27/08/2014

The, I don't know, dangers, maybe? of museum catalogues...

The only thing I did was to make another spinning wheel search, this time on the site of Murbergets museum.

After some dead tries I finally found out how to search the whole site, and got some 150 hits.

Several were not spinning wheels (even though they were so tagged), and most wheels had no pictures.

As I was clicking through the detail pages, I came across this text.

Due to the extraordinary text, I felt I had to let you all know how a spinning wheel can be described (my translation, which probably can be re-written to something more fluent, but I think this captures the flavour of the original)(Swedish original below):

Material: Wood, Metal

Technique: Turned, Nailed

Function: To ply thread(s)

Monogram - Initials - Writing: IE Holm

Maker - Location - Affirmed: Teodor Bylund

[The] spinning wheel is used to make thread/yarn from textile material (wool/flax). The wheel itself makes the flyer move. The treadle makes the wheel go round.

The spinning wheel consists of several nicely turned wooden parts. The "table" has three legs, of which two are connected to a crosspiece which also houses the treadle. From the treadle there is a vertical shaft leading to an S-shaped iron. This is an axle, which goes through forks and wheel. The two forks have an upright each, everything fastens to the "table". The "table" is slanted. The flyer mountings are located behind the wheel. A bigger lump comes up and is penetrated by a horizontal stave, at the ends of which two pillars are mounted, the flyer sits between these. The distaff's mounting piece is located at the back end of the table. Newly turned (1991) by Teodor Bylund. The head of the distaff has its own number 13918. At the back end there is a knob for carrying. Drive band is missing. Marked "I E Holm".

(No, I have not used google translate, or any other translation software... it really (REALLY) says there is a bigger lump coming through the table, and that there is a carrying knob at the back end. Try google translate yourselves, if you don't believe me!)

It is a pity there is no picture - I would have liked to see this obviously very different MOA construction.

However, for those of you having trouble with lumps and forks, here are two annotated pictures (click for readability):

OK, IF you have used the auto-translate, read the text on the museum site instead! The auto-translate makes the original Swedish totally... strange.

Material: Trä, Metall

Teknik: Svarvat, Spikat

Funktion: Tvinna tråd

Monogram - Initialer - Påskrift: I E Holm

Tillverkare - Tillverkningsort - Säker: Teodor Bylund

Spinnrocken används för att göra tråd/garn av textilmaterial (ull/lin). Själva hjulet ser till att vingspindeln rör sig. Trampan sätter fart på hjulet.

Spinnrocken består av flera fint svarvade trädelar. "Bordet" har tre ben, varav två fäster nedtill i en tvärslå där också trampan sitter. Från trampan leder en vertikal axel till ett S-format järn. Detta är en axel, vilken löper genom gafflar och rockhjul. De två gafflarna har varsin stötta, alltsammans fäster i "bordet". "Bordet" är snedvinklat. Bakom hjulet sitter vingspindelns fästanordning. En större klump går upp och genomborras av en horisontell stav, i vilkens ändar två pelare fästs, vingspindeln sitter mellan dessa. Längst bak på bordet sitter rockhuvudets ställning. Nysvarvad (1991) av Teodor Bylund. Rockhuvudet eget nummer 13918. Längst bak en knopp att bära i. Drivbandet saknas. Märkt: "I E Holm".

29/04/2014

April shuttle

This year, I forgot about the April spools day until way too late.

However, on the last week-end of April, all glassworks hereabouts open their new summer exhibitions - for some reason they always (?) choose not to show pictures... Anyway, we went to Kosta, where I found this:

It was just a detail in a biggish (3 x 3 m?) installation by Bertil Vallien (and I neglected to take an overview picture).

In the second picture you can clearly see that it once was a genuine hand shuttle. (Click to biggify)

Innovative? Or sad?

(Here are a couple more pictures from our "arty" trip on the Saturday.)

18/02/2014

How to spin better linen yarns

Many authorities "of the time" assert that yarn spun with "the new method" (ie with a DFW of the Mager type) has a much, much better quality - as if consistent grist and twist come automatically with the wheel type. (Maybe it does... after all, I haven't got mine operational yet)

To let you all know as much as I now do, I took a stab at translating the first part of the Book with the Hopeless Title - the part that should instruct us all how to use this famous wheel.

(It can be that you, too, become a bit disappointed with the contents. But I assure you: this is all there is!)

The first part, same as the other, is now available in .pdf-form, the translated variant here with text in both Swedish and (my attempt to translate it into) English. The plate is on the very last page. (Comments on the translation(s) are most welcome!)

There is also the "original" (transcribed, some sort of Swedish) - found here. The drawing is on the last page.

For my local-ish Swedish friends: do you know anything about the Gårdsby Lin-Institut, at Gårdsby outside Växjö, that was in existence 1811-1827 (or -28)? There is a rumour that they used double flyer wheels there, too, but as the Mager type was not known until 1843, I would be very interested to know what kind of DFWs they were using.

To let you all know as much as I now do, I took a stab at translating the first part of the Book with the Hopeless Title - the part that should instruct us all how to use this famous wheel.

(It can be that you, too, become a bit disappointed with the contents. But I assure you: this is all there is!)

The first part, same as the other, is now available in .pdf-form, the translated variant here with text in both Swedish and (my attempt to translate it into) English. The plate is on the very last page. (Comments on the translation(s) are most welcome!)

There is also the "original" (transcribed, some sort of Swedish) - found here. The drawing is on the last page.

For my local-ish Swedish friends: do you know anything about the Gårdsby Lin-Institut, at Gårdsby outside Växjö, that was in existence 1811-1827 (or -28)? There is a rumour that they used double flyer wheels there, too, but as the Mager type was not known until 1843, I would be very interested to know what kind of DFWs they were using.

20/01/2014

Speaking of linens

Look what I found in a local, um, curiosity shop (she would be offended if I called it a flea market - ):

The printing says, from left to right: (logo) pillowcase material (with a rather odd spelling: örngåttsväf When was it spelled "örngått"?); shrunk; linen finish (what is that? Calendered?); 28 metres; free from sizing. (I should mention that it is cotton.)

The "bale" now held 12 metres, according to the label. Even with a very nice hand, what could I do with 12 metres of pillowcase material (this means it is 62 cm wide - or 62 c/m, as the print says)? So I let it stay at the shop...

Because of that, I can't give you a thread count - but I doubt it is less than 40/cm. On the other hand, it is machine-spun.

Come to think of it - how many textile-y "everyday" words are there that are mis-used? Bed linens became cottons many years ago, but are still called linens. A friend of mine (a weaving teacher) says it is quite ok, that it is in fact standard in industrial parlance, to use the word "silk" for any very long fibre - extruded viscose, for instance. (Like "silk velvet")

The printing says, from left to right: (logo) pillowcase material (with a rather odd spelling: örngåttsväf When was it spelled "örngått"?); shrunk; linen finish (what is that? Calendered?); 28 metres; free from sizing. (I should mention that it is cotton.)

The "bale" now held 12 metres, according to the label. Even with a very nice hand, what could I do with 12 metres of pillowcase material (this means it is 62 cm wide - or 62 c/m, as the print says)? So I let it stay at the shop...

Because of that, I can't give you a thread count - but I doubt it is less than 40/cm. On the other hand, it is machine-spun.

Come to think of it - how many textile-y "everyday" words are there that are mis-used? Bed linens became cottons many years ago, but are still called linens. A friend of mine (a weaving teacher) says it is quite ok, that it is in fact standard in industrial parlance, to use the word "silk" for any very long fibre - extruded viscose, for instance. (Like "silk velvet")

16/01/2014

What I have been doing - nerd alert

It all started with the DFW (Double Flyer Wheel).

I wanted to know where it came from (or, at least, from whereabouts in the country this kind of accelerated driving was known). I had seen something in a (borrowed) book - had to buy it for myself. Was sort of disappointed - there was a wheelwright mentioned, that much was right, but, as it were, only in passing. He had a name and a year (Abraham Hedman, 1738), but that was all there was.

I (thought I) knew I had seen something like it, many years ago, in a museum. Thought I knew which museum. Wrote to them. Wrote to several more museums, while I was "at it". Result: nothing, nada, zilch. A month later, ONE of the (by now 6) museums answered: "I don't have time to go out in the storehouse to look".

Meanwhile, I got a couple of obscure books on ILL, one of them very dull-looking: Den Ångermanländska linslöjden, en historik. (The linen works of Ångermanland, a history). It is a dull text, but once I started to really read it I found lots of, hm, nuggets(?). And lots of food for nerding...

So, here, friends, goes:

Definition of "prime linen": as you (probably will not) remember, "prime linens" come in many classes. They were (at least most of them) 1 1/2 aln (3 ft, or 88-89 cm) wide.

For class 1 there were 2720-2920 ends (or 30-32 ends/cm); for class 8 (which was NOT the finest seen) there were 4120-4 320 ends (or 45-48 ends/cm).

The History book contains some well-described examples, complete with old (and obscure) weights-and-measures.

So I got out the calculator...

One example was described as 39 alnar, 4 1/2 skålpund; 3600 ends, woven in 2299-dent reed.(If I did my calculations right, this means the cloth was 23,2 m long, weighed 1,9 kg - which would translate to 81,9 grams/metre fabric).

OK.

3066 ends x 23,2 metres of cloth = 83 520 metres of warp yarn.

But we have a weft, too. For convenience, I assumed 40 picks per cm (warp density comes out as 40,5) - which gave me another 83 500 metres.

Which gives a total of about 167 000 metres per 1,9 kg of weight.

Now, linen is numbered in Nel (Number English Linen, I believe), where the number tells how many skeins of 300 yards is accommodated in 1 imperial pound.

One yard is 0,91 metres, so 300 yards = 274 metres (rounded), which means we have 167 000 / 274 = 609,5 skeins - let's round a bit carelessly, say 600 skeins.

As an imperial lb (of today) is approx. 0,45 kg, we can go on: ( 600 / 1900 grams) x 450 = 142 (rounded)

which means this particular cloth was woven with a linen singles (*all* "lärft" is singles) of a number somewhere in the vicinity of 140/1. Handspun.

I did several calculations, approaching from different angles, 'cos I was thinking I had made a decimal error somewhere.

But - all of them came up more or less the same. There were several examples described, and they all came out with a yarn count between approx. 120 to 150. Handspun!

A picture from the book, divided in two to make it possible (I hope) to read the writings.

The caption says, roughly;

"These two photos show the strip, with thrums, cut off from the cloth for which Catharina Andersdotter got the Illis Quorum [a royal medal]. The cloth is of the seventh class, is woven through a weaving reed of 2 200 dents, contains 40 knots, or 4000 ends of warp. Every square centimetre thus counts to 40 ends of warp and circa 37 picks of weft. We have found this linen strip in the royal archives [... something "administrative" I can't translate] 1808 - 1811."

I wish... Or, on second thought, maybe not :-)

But the DFW?

Nothing much. This book tells about several "spinning schools" and some competitions - it seems that the DFW spinners always won, but that did not convince "the people". One of the arguments was that a DFW is harder to spin on (heavier to treadle, needs more concentration), and therefore, even if you are more productive/efficient for the first hour(-s - the competitions were 2 hrs), you can't spin for as many hours as a "prime spinner" usually did. Right or wrong?

Anyway. I still don't know anything about my DFW, it still doesn't work (too cold to do what needs to be done on it, the workshop is unheated) - and the only accomplishment I have done is to amass a lot more "worthless knowledge".

Here is another picture from the book:

which shows another principle for a DFW: one MOA, two flyers. Therefore it has to have two drive bands, I think - and imagine tying two drive bands so that the tensioning works for both, at the same time...?!?

Waiting for more ILL books, and perhaps I have to do some "hands-on" museum search, and...

15/01/2014

M PET:SON

Yes, I'm still here.

And one of these days, I'll tell you about what I have been doing: nerding. (Can it be used as a verb? It certainly feels like it...)

Meanwhile, let me present one of my old spinning wheels, name of Findus (not a very good pic, but the best I could do - many discarded pics before this...)

Here is the maker's mark:

For the Swedes, it will now be obvious (I think) why he is called Findus. For all others: Findus is a cat who owns an old man called Pettson - many delightful (children's) books, issued by Opal bokförlag. (It seems some of them are translated to English. I highly recommend them to all cat lovers out there, no need to have children as an "excuse"...)

Since I love both Findus and his old man, and it did not work to link to "his" pages on Opal, I decided to help you non-Swedes with a link to amazon - here goes: http://www.amazon.com/s/ref=nb_sb_noss_2?url=search-alias%3Dstripbooks&field-keywords=Nordqvist%2C%20Sven

And one of these days, I'll tell you about what I have been doing: nerding. (Can it be used as a verb? It certainly feels like it...)

Meanwhile, let me present one of my old spinning wheels, name of Findus (not a very good pic, but the best I could do - many discarded pics before this...)

Here is the maker's mark:

For the Swedes, it will now be obvious (I think) why he is called Findus. For all others: Findus is a cat who owns an old man called Pettson - many delightful (children's) books, issued by Opal bokförlag. (It seems some of them are translated to English. I highly recommend them to all cat lovers out there, no need to have children as an "excuse"...)

Since I love both Findus and his old man, and it did not work to link to "his" pages on Opal, I decided to help you non-Swedes with a link to amazon - here goes: http://www.amazon.com/s/ref=nb_sb_noss_2?url=search-alias%3Dstripbooks&field-keywords=Nordqvist%2C%20Sven

15/11/2013

On double pulleys and no horses (warning, long)

(I should have been sewing, but the pins are too fiddly for the wrenched wrist. So I have been reading, instead.)

I started with Gertrud Grenander-Nyberg's Lanthemmens vävstolar (1974, ISBN 91-7108-076-7). On pages 287 f she writes about double pulleys (my translation; my comments in italics):

For plain weave, threaded on four shafts, there was a pulley type seldom used nowadays, namely two pulleys mounted on the same axle. The pulleys can be of different size. For the tying, the outer shafts were tied with the cord over the bigger pulley, which made the shaft tieup clearer (simpler?)

Important words here: CAN be of diff size. In most (all?) pictures I've seen they have been of the same (or so near the same as possible) size. (Had they been different size, they could have been called "horizontal dräll pulleys"? Has anyone seen an example of that (ie with more than two pulleys)? Edit: here.

The Finnish textile technician Helvi Pyysalo has showed that two pulleys on the same level can be used for four-shaft even-sided twill by connecting shafts one and three over one pulley and shafts two and four over the other pulley.

With this method follows that, when the shafts are lowered in pairs in four different combinations, the cords on both pulleys will move, which is (recommended, necessary? - "good") to get a clear shed.

I don't understand that: does she say that for EVERY shed on a CB loom "both cords should move"? If so: why?? Or what is it I don't understand here? With one pulley and horses that is not always the case, but sheds can be good anyway.

This can happen not only with two pulleys on two axles on the same level but also with the pulleys mounted on the same axle like on a double pulley.

Is there a difference in appearance in the two described above? (for "double pulley" she uses the Swedish "parblock", so in the text there is a distinction between the two types here.) ETA: see picture here.

It is likely that the double pulleys were used in this fashion in older times for weaving even-sided twill. With the pulleys on the same level the upper tieup was lower than if it was accomplished with several tools on different levels. Double pulleys were therefore an advantage when using the oldest looms which have low castles. This can be an explanation to the numerous double pulleys from the older times.

Nowadays, for four shafts, usually only one of the pulleys is used in combination with horses.

Same author, 25 years later, in Linnelärft i Ångermanland (2001, ISBN 91-7108-480-0), has slightly changed her ideas.

Background, about "premielärft" - roughly "prime quality linen cloth": in 18th century the "powers" divided the country and decided Ångermanland was the region to grow flax and (spin and) weave linen. To make the people more enthusiastic about it, certain standards were set, and those who fulfilled them got extra pay.

Anyway. According to Grenander, weavers of prime cloth were specialists, using special looms. Those looms were often shallower than "allround" looms - sources from the time state that an allround loom was usually about 2 1/2 aln (about 5 ft), while linen looms were only 2 aln (4 ft).

The reasoning behind that is (apart from the fact that German linen looms often were shallow) that the "free" warp is shorter, and therefore less exposed to wear (p 99).

Something I don't understand here: as linen is not elastic, shouldn't it benefit from a longer "free" warp, by distributing the stretch over a longer section?

(She goes on to say that plain weave needs less loom-depth than multi-shafted cloth, which is of course true.)

She also thinks that the double pulleys, at least those with short uprights, were used primarily by these specialist weavers.

(To me it is not clear exactly how she came to that conclusion.)

On p 103 she writes that, because of the fineness of the prime cloth, the warps had to be distributed over four shafts, and therefore the double pulleys were "the most efficient". Thus looms with double pulleys were, together with very fine reeds, the most typical tools of a "prime" weaver.

I'm still unsure of why double pulleys are "the most efficient"...

Anyway, it is apparent that she has changed her mind over the 25 years between her thesis and her last book - from thinking that double pulleys were, in effect, "old-fashioned", to thinking they were the mark of a specialist.

Just for curiosity: "prime linens" came i 8 classes. They were (at least most of them) 1 1/2 aln (3 ft, or 88 cm) wide.

For class 1 there were 2720-2920 ends ( or 30-32 ends/cm); for class 8 (the finest) there were 4120-4 320 ends (or 45-48 ends/cm). (from Uppfinningarnas bok, band 6 from 1873.

And this, my friends, was all handspun singles!

I started with Gertrud Grenander-Nyberg's Lanthemmens vävstolar (1974, ISBN 91-7108-076-7). On pages 287 f she writes about double pulleys (my translation; my comments in italics):

For plain weave, threaded on four shafts, there was a pulley type seldom used nowadays, namely two pulleys mounted on the same axle. The pulleys can be of different size. For the tying, the outer shafts were tied with the cord over the bigger pulley, which made the shaft tieup clearer (simpler?)

Important words here: CAN be of diff size. In most (all?) pictures I've seen they have been of the same (or so near the same as possible) size. (Had they been different size, they could have been called "horizontal dräll pulleys"? Has anyone seen an example of that (ie with more than two pulleys)? Edit: here.

The Finnish textile technician Helvi Pyysalo has showed that two pulleys on the same level can be used for four-shaft even-sided twill by connecting shafts one and three over one pulley and shafts two and four over the other pulley.

With this method follows that, when the shafts are lowered in pairs in four different combinations, the cords on both pulleys will move, which is (recommended, necessary? - "good") to get a clear shed.

I don't understand that: does she say that for EVERY shed on a CB loom "both cords should move"? If so: why?? Or what is it I don't understand here? With one pulley and horses that is not always the case, but sheds can be good anyway.

This can happen not only with two pulleys on two axles on the same level but also with the pulleys mounted on the same axle like on a double pulley.

Is there a difference in appearance in the two described above? (for "double pulley" she uses the Swedish "parblock", so in the text there is a distinction between the two types here.) ETA: see picture here.

It is likely that the double pulleys were used in this fashion in older times for weaving even-sided twill. With the pulleys on the same level the upper tieup was lower than if it was accomplished with several tools on different levels. Double pulleys were therefore an advantage when using the oldest looms which have low castles. This can be an explanation to the numerous double pulleys from the older times.

Nowadays, for four shafts, usually only one of the pulleys is used in combination with horses.

Same author, 25 years later, in Linnelärft i Ångermanland (2001, ISBN 91-7108-480-0), has slightly changed her ideas.

Background, about "premielärft" - roughly "prime quality linen cloth": in 18th century the "powers" divided the country and decided Ångermanland was the region to grow flax and (spin and) weave linen. To make the people more enthusiastic about it, certain standards were set, and those who fulfilled them got extra pay.

Anyway. According to Grenander, weavers of prime cloth were specialists, using special looms. Those looms were often shallower than "allround" looms - sources from the time state that an allround loom was usually about 2 1/2 aln (about 5 ft), while linen looms were only 2 aln (4 ft).

The reasoning behind that is (apart from the fact that German linen looms often were shallow) that the "free" warp is shorter, and therefore less exposed to wear (p 99).

Something I don't understand here: as linen is not elastic, shouldn't it benefit from a longer "free" warp, by distributing the stretch over a longer section?

(She goes on to say that plain weave needs less loom-depth than multi-shafted cloth, which is of course true.)

She also thinks that the double pulleys, at least those with short uprights, were used primarily by these specialist weavers.

(To me it is not clear exactly how she came to that conclusion.)

On p 103 she writes that, because of the fineness of the prime cloth, the warps had to be distributed over four shafts, and therefore the double pulleys were "the most efficient". Thus looms with double pulleys were, together with very fine reeds, the most typical tools of a "prime" weaver.

I'm still unsure of why double pulleys are "the most efficient"...

Anyway, it is apparent that she has changed her mind over the 25 years between her thesis and her last book - from thinking that double pulleys were, in effect, "old-fashioned", to thinking they were the mark of a specialist.

Just for curiosity: "prime linens" came i 8 classes. They were (at least most of them) 1 1/2 aln (3 ft, or 88 cm) wide.

For class 1 there were 2720-2920 ends ( or 30-32 ends/cm); for class 8 (the finest) there were 4120-4 320 ends (or 45-48 ends/cm). (from Uppfinningarnas bok, band 6 from 1873.

And this, my friends, was all handspun singles!

Labels:

counterbalance looms,

curiosities,

looms

Subscribe to:

Posts (Atom)